So, I fell behind on my weekly posts already. To be honest, I didn’t do a lot in week 2. Well, nothing interesting. I was still quite exhausted from the first week; I really cannot emphasize how physical dyeing large quantities of yarn can be. I took it easy this week, mostly because I needed to. While I enjoy what I do and I want to do it all the time, my body just can’t keep up. Oh, the joy of being in my 30s and realizing my body doesn’t bounce back like it used to. I imagine that people who were/are dyers by trade must be sore quite often.

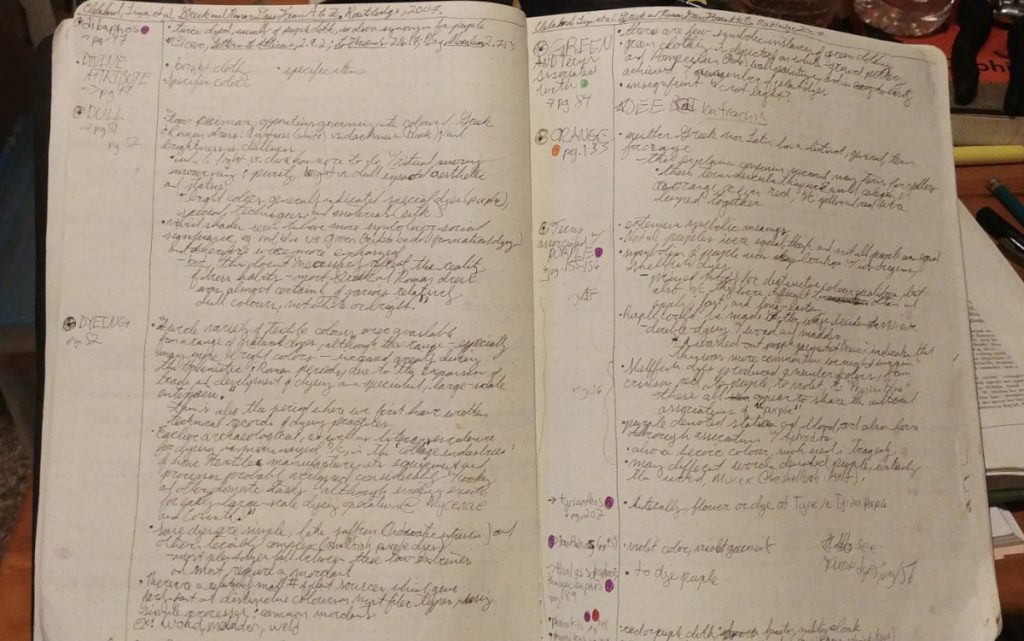

This isn’t to say I didn’t do anything – I did. The first thing was overdyeing my yarn dyed with madder and the yarn dyed with woad that I set aside for the inlay pattern. The madder gave the yarn a very nice pinkish orange color, but I wanted it redder, so I used cochineal to do the job. I truly enjoy working with cochineal. Not only does it give an amazing array of colors, it was important to my ancestors, which is a connection I hold dear. Now, I know how to make pure red with cochineal, but I decided to process it in a way to give more of a magenta – it’s the easiest color to get, and I figured the madder-dyed yarn already had a warm undertone to it and adding more of that wouldn’t make much of a difference.

Whole cochineal insects

Finely ground cochineal

Cochineal with a bit of water. In Nahuatl, cochineal is called nocheztli – “cactus blood”. Rather fitting, yes?

And I succeeded! Sort of. It’s a a bit of a subtle difference, but it’s there. I left the yarn overnight in the cochineal bath in order for the yarn to soak up as much pigment as possible, which it did with the inlay yarn but not so much the madder-dyed yarn. I have a feeling that if I mordanted the yarn again it would soak of more of the cochineal, but I didn’t really want to keep subjecting the yarn to high temperatures. Also, while the color wasn’t quite what I wanted originally, I’ve grown to quite like it.

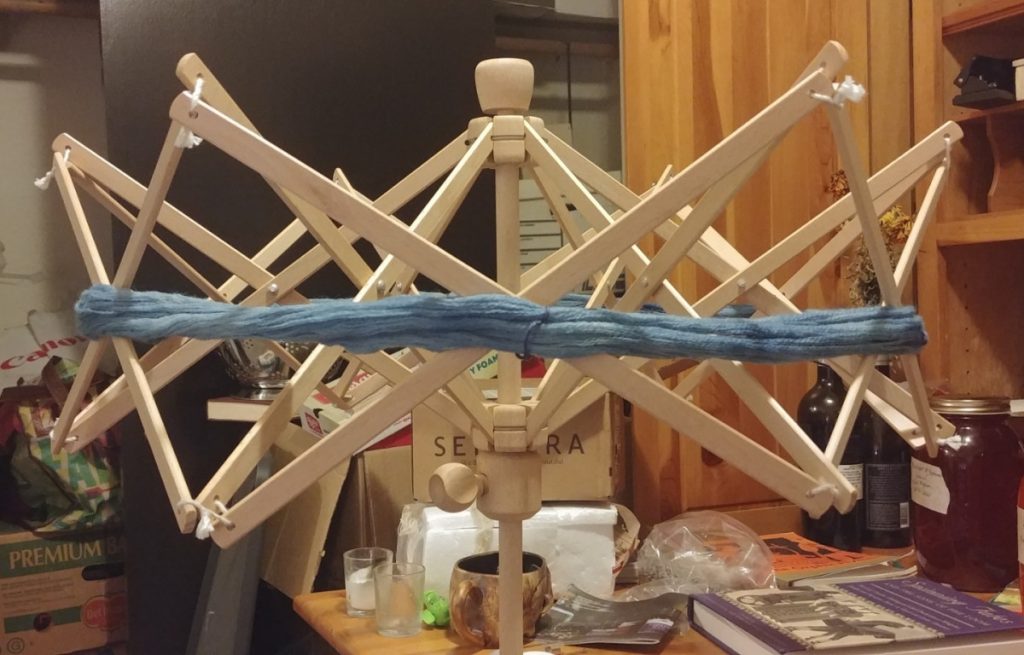

The other major thing I did was wind ALL of the yarn into balls. This…took a while. For some reason, the warp yarn felted a bit when I was dyeing it with woad. I honestly don’t know why – the woad bath wasn’t heated nor did I agitate the yarn at all. I had to separate the strands of yarn from each other before I could wind it up. I also decided at the last minute to buy a yarn swift. A yarn swift holds a skein of yarn and spins. Without it, I would have had to ask my partner to help me by holding the skeins while I wound it. The yarn swift was a bit pricey, but worth every cent. I thought winding the yarn into balls would be a quick task, but it really wasn’t. I feel like that right there is the theme of this whole project: I thought x would take a certain amount of time, but actually takes a great deal more of time than I thought.