The Finished Hive

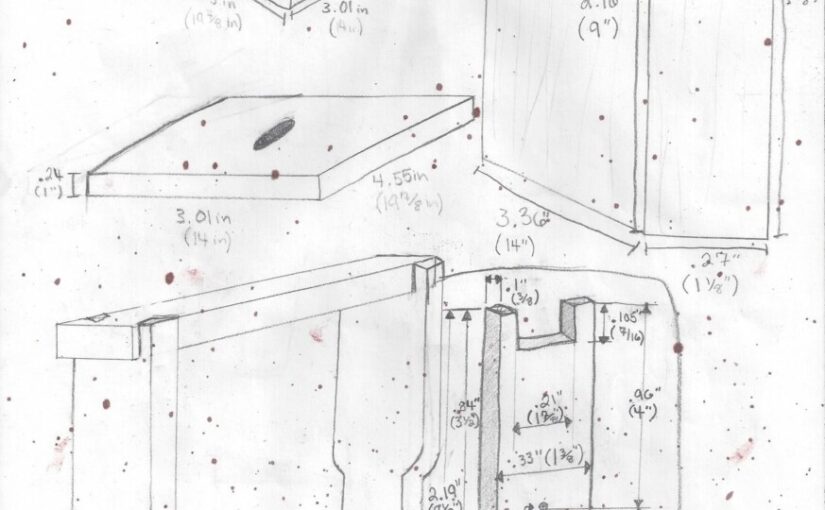

Making Frames

Because the dimensions of my cavity had to be altered from the traditional Langstroth hive, I couldn’t purchase commercially available frames. Because of this, I had to fabricate my own to fit the dimensions of my hive. Using slats of hemlock recycled from a ceiling fixture in TESC library, I followed publicly available blueprints for Langstroth frames, only tweaking the length and height in the design.

Unfortunately, when my frames were finished, they did not fit in the hive all the way. It appears that the the top bars were slightly too long, splaying out the top of the frames enough to prevent them from fitting.

To fix this, I simply removed a small amount of material from the cavity walls to make space, rather than changing each of the frames. I did this using large chisel and mallet, and the frames now fit comfortably inside the hive.